Error-free production

Dieter Hellwig (Purchasing Quality and Technology Experts and Methods (M/PQT10.1) | Robert Bosch GmbH)

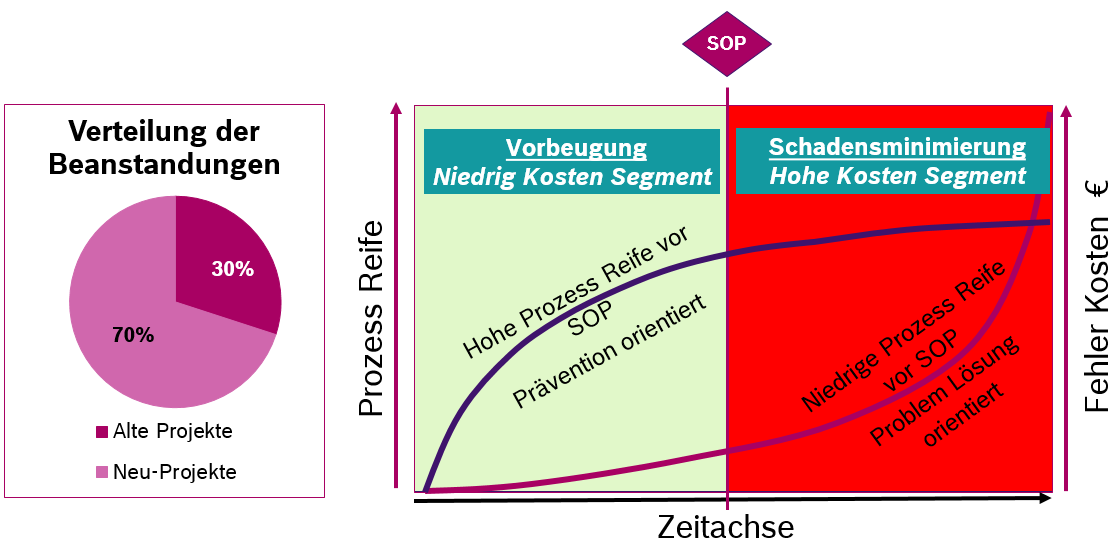

How can we maximise the benefit of FMEA for the company? E.g. by minimisation of complaints from new projects, for instance.

1. Objective (Why?)

Can you imagine a 3-star chef with a knife so blunt?Just as sharpening knives makes a significant contribution to cooking, sharpening the method in the figurative sense contributes substantially to the benefits of FMEA.

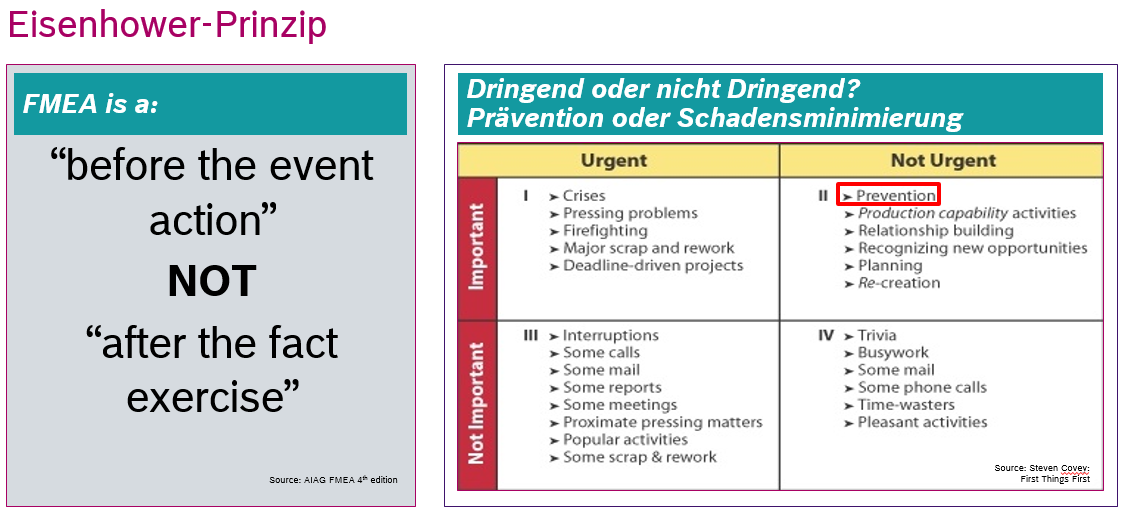

The description in English from the AIAG manual claims, that the P-FMEA is a "Before the event" activity and not an "After the fact" exercise. Those FMEA's, which are mainly used afterwards in series production, do not use the full potential of the FMEA methodology. That is what proves it ineffective and expensive.

Whether or not one benefits from P-FMEA is primarily determined by the attitude and way of thinking in the company and in particular by the skills of the moderator and is only influenced by academic or methodological approaches in the second instance.

Where is the FMEA located in your company?

2. Procedure (How?)

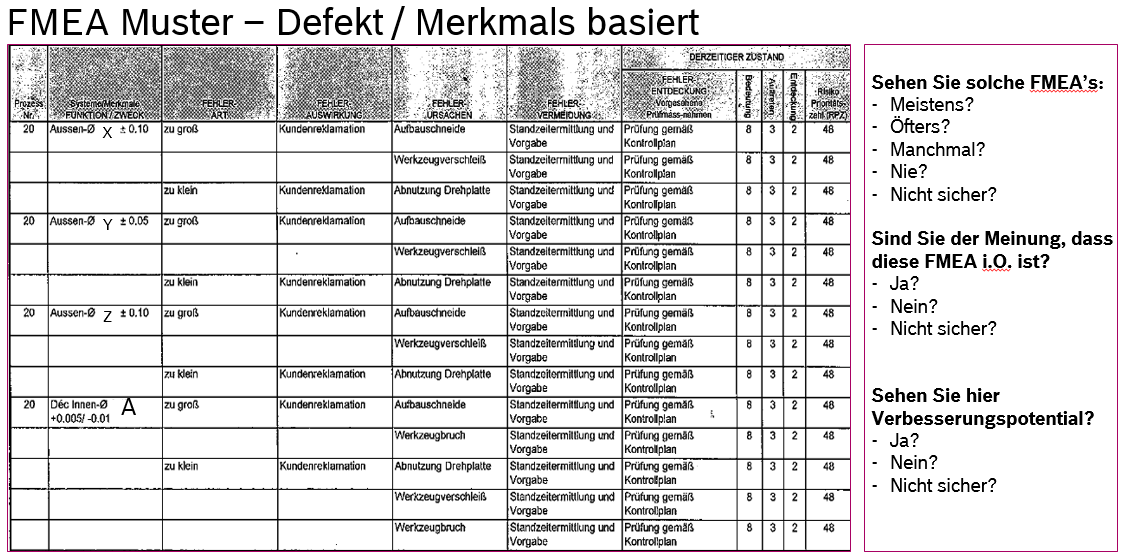

The use of a "structure based P-FMEA" versus a "defect / feature based" P-FMEA places the malfunctions in the process in the limelight rather than the error pattern or feature. An overview matrix (analogous VDA risk matrix, but without colours) increases the transparency of an FMEA. Of course, the FMEA is meant to prevent SOP and not revise the FMEA afterwards with the help of the 8D-report. And finally, the use of the new VDA / AIAG manual prevails upon new standards and increases the benefits.

Example:

Here is an example of a typical error / feature based FMEAYour assessment. What is the benefit of an error / feature based FMEA for the company?

3. ResultThe FMEA moderator makes an essential contribution to derive benefit from FMEA. The real momentum comes from mutual discussion and understanding of the cause-effect relationships within a team environment.

Here are a few questions:

- What benefits do you expect from your FMEA?

- What benefit does your management expect from the FMEA?

- Where exactly are your main complaints regarding series production and can the FMEA method make a positive contribution here?

- Which of the strategies would work in the interest of escalating the FMEA-benefits for the organisation?