FTA fault tree analysis part I

1. Objective (why?)

- Quantitative statement on the likelihood of the occurrence of a safety-critical top event.

- Qualitative presentation of logical connections from the top event to the cut sets (understanding of the functionality of the system).

- Input to verify the system property “functional safety” for ASIL A - C according to ISO 26262 (top event = negation of the safety target).

- Statements about the availability of a system while taking into account repairs (analysis in plant engineering).

(Fault tree analysis is used to implement the necessary robustness and the system property of functional safety for design results based on deductive analysis results and any necessary system optimizations.)

2. Procedure (how?)

Prerequisites:

- The top event must be known.

- Detailed knowledge about the system structure must be present.

- The component failure rate must be known.

- The likelihoods of occurrence for the component failures must be known.

- To calculate non-availability, the repairs for the components must be known.

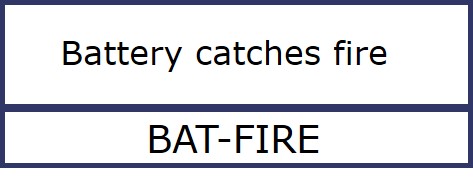

1. Define top event

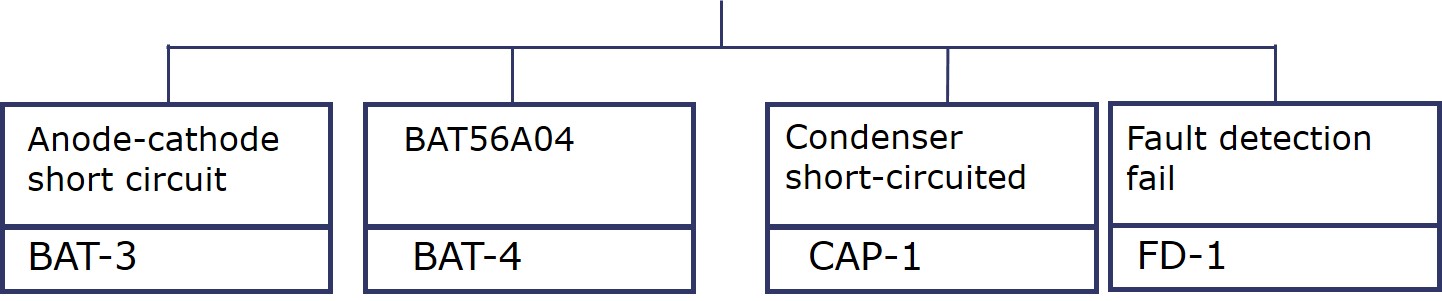

2. Ascertain failures and conditions as well as failure combinations that may be the cause of the top event.

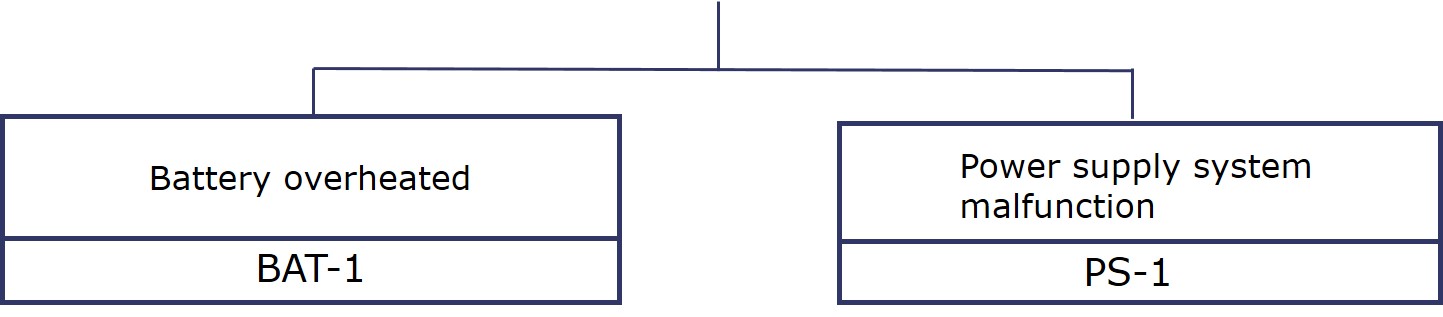

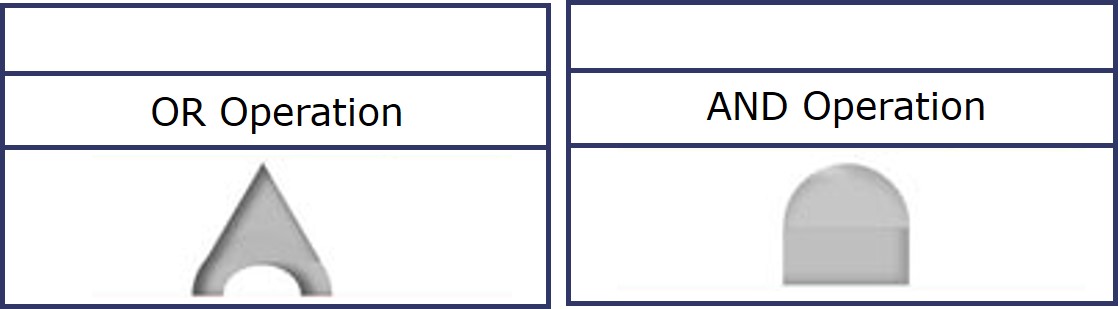

3. Logical linking of the failure and conditions (and/or links) – top-down

4. Repeat procedure until independent basic events are identified (cut sets)

5. Assign the known failure rates to components for the identified basic events and calculate the likelihood of the top event while taking into account the logical links.

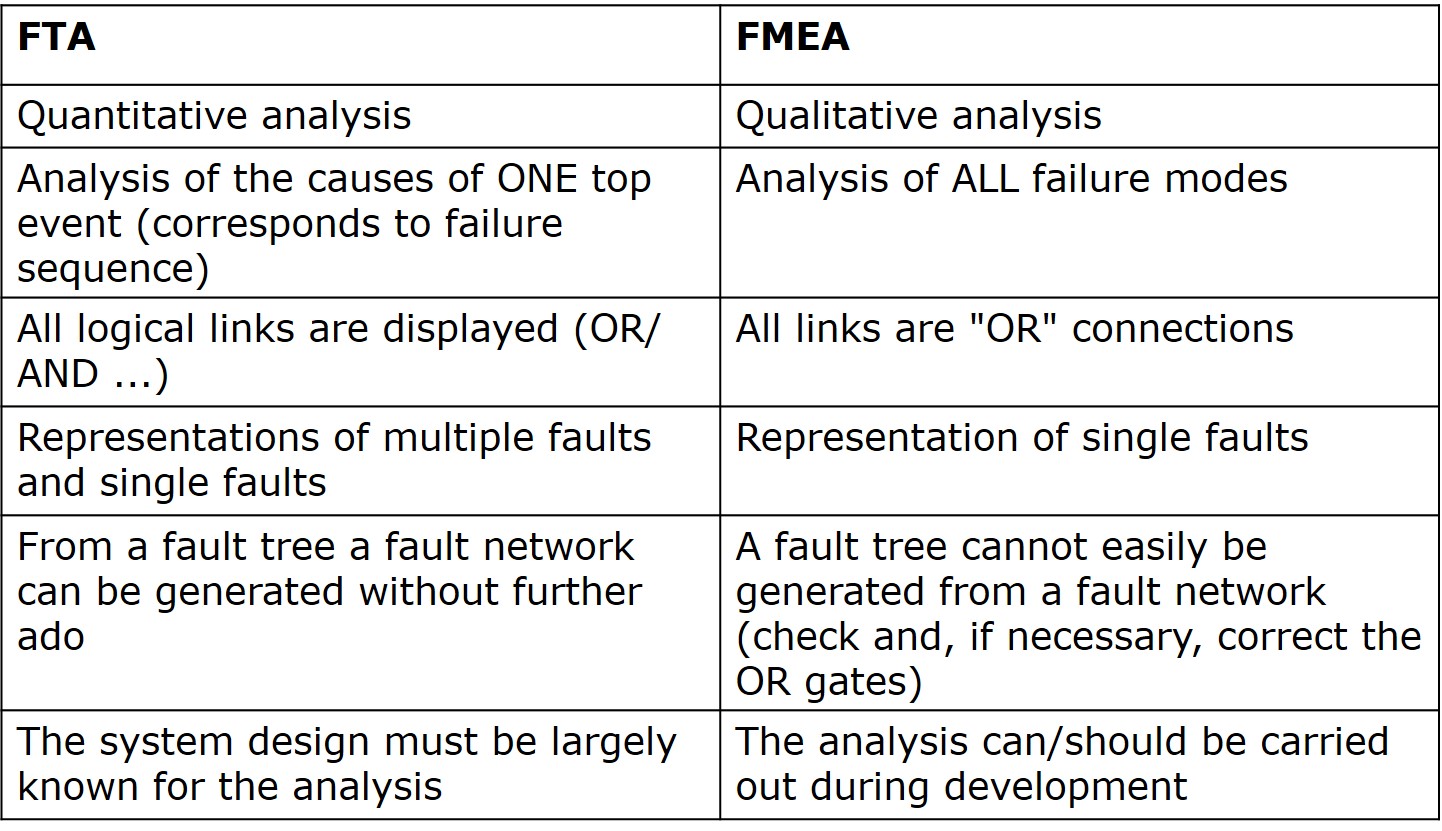

Differences from FMEA