The load with Special Characteristics in FMEA

by Dr. Uwe-Klaus Jarosch (Benteler Automobiltechnik GmbH)

How does FMEA help to determine Special Characteristics? A proposed solution.

FMEAs describe technology. Special Characteristics (SC) are required in some industries, such as to add technological exclamation marks. The article presents how the FMEA tool helps to determine SC with 3 additional rules.

1. Objective (why?)

Area of conflict: IATF 16949 requires Special Characteristics (SC) and their tracking as part of risk management = FMEA.

VDA+AIAG ban SC from the Design FMEA.

Some companies derive SC from the FMEA, although this does not work.

What does a solution look like here?

- What is special about SC?

- Technical standards as the basis for decision-making

- Criteria for filters and determining SC

- Quality classes

- Integration in FMEA templates.

Clarification: What is special about Special Characteristics and how can the FMEA tool help to determine them?

Distinction between risk assessment and determining specific technological characteristics.

Limitation of the quality requirements to what is technologically necessary.

2. Procedure (how?)

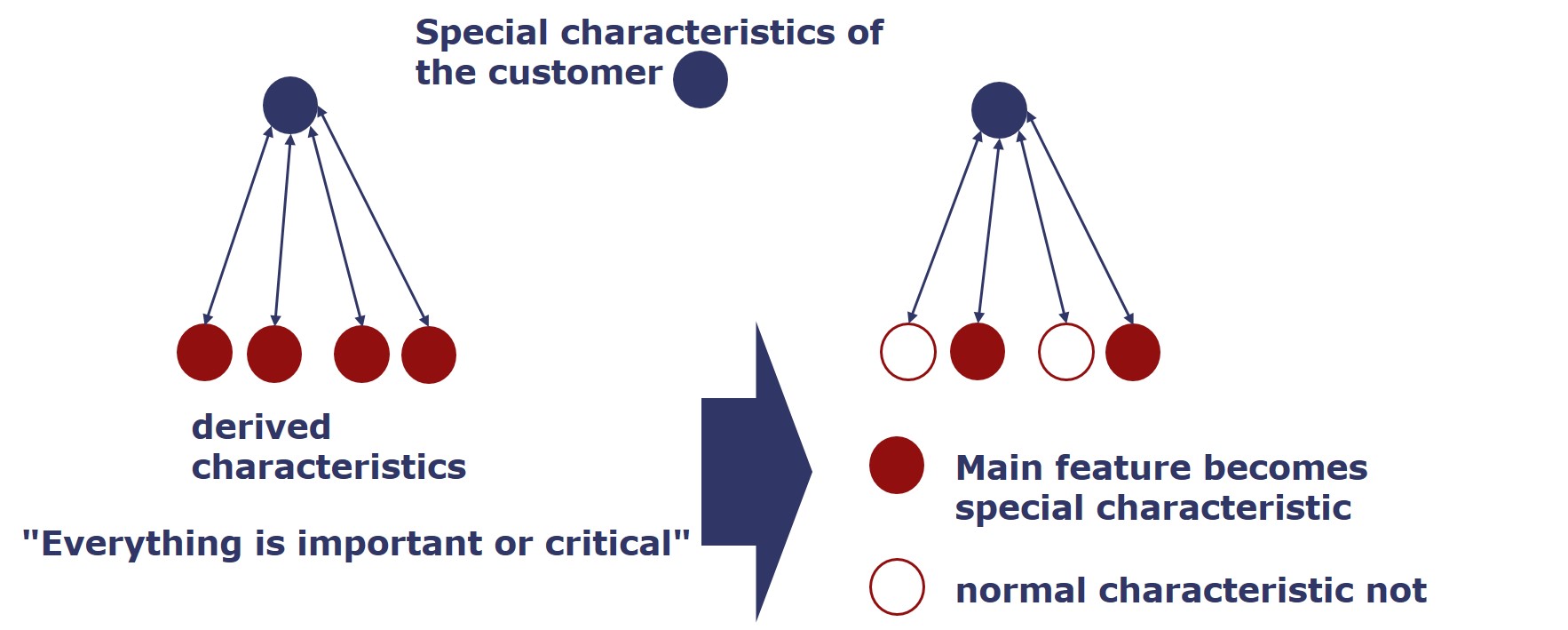

The client specifies the criticality.

Technological knowledge determines areas of focus = main characteristics in the connections network

The FMEA logic is supplemented by rules from which project-related determinations on the SC can then take place.

The company’s experiences determine how high the quality requirements must be for SC.

Example:

In a chassis component, the OEM and supplier agree that this welded joint is critical = BM-S or CC.

The welded joint is a design element in itself, the properties of which are described by approx. 20 product characteristics and possible failure patterns. A similar number of process characteristics are involved in producing this welded joint.

All 40 characteristics have a severity of S = 10 as they are involved in the fault tree.

All characteristics have some kind of influence on the result.

But which characteristics have an influence that justifies referring to them as Special Characteristics?

Engineering knowledge tells us that there are main characteristics which, when safeguarded in the process, also safeguard the main product characteristics and thus also the fulfillment of function overall. -> Technologists determine which product and which process characteristics are main characteristics.

If there is any ambiguity, either “a little more” can be chosen or – better – a statistical evaluation can be made with ZDF as to which are essential and also correlated contributions. Like determination procedures, limit values are also part of the company expertise. This creates a basis for argumentation in the company that is also transferrable.

3 rules describe the logic with which a main characteristic becomes a Special Characteristic:

A characteristic must be a main characteristic to become a SC.In the FMEA fault tree or the FTA, minimum severity values are achieved and connected.

A SC is specified on the next level up.

The 3 rules will make CC characteristics out of the main technological characteristics for this use case in the D-FMEA. The same 3 rules continue the chain in the P-FMEA in order to make the main characteristics of the process into Special Characteristics based on the application.

The same technological connections apply to another welded joint. As this welded joint is not required as a SC, there are no SCs here.

Process characteristics can influence several product characteristics. If none of the product characteristics is a main characteristic, none of these process characteristics will also become a SC.

If, however, only one of the influenced product characteristics is a main characteristic, there will also be SCs for the process characteristics.

There is now the question of the test requirements for these characteristics.

The client, like the supplier, wants this welded joint to function reliably over the service life.

Typical capabilities or 100% tests will not be available – at least for most product characteristics of the welded joint. And will also not be seriously required. How good must the characteristics be, then, to reliably fulfill the functional expectation?

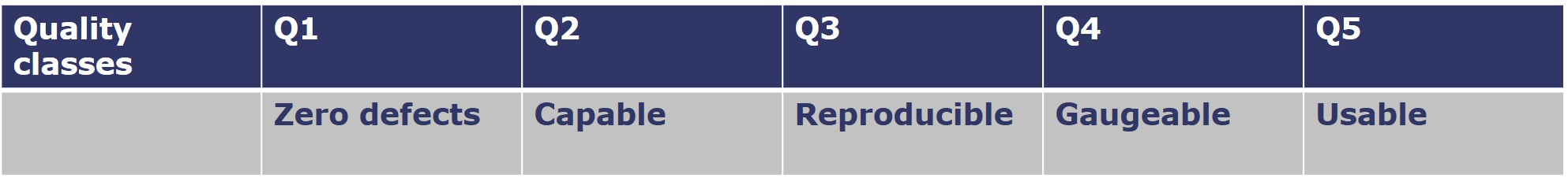

A 5-stage system of quality classes was thus developed that ranges from zero-error quality (= Q1) and the “normal” capability requirement cpk≥1.33 = Q2 to the occasional evidence of the property (Q5).

For most main characteristics within a welded joint, destructive tests are regularly performed that are prepared and measured by means of grinding. The dynamics of the welding process, however, inevitably lead to local fluctuations, so compliance with the specified tolerance usually satisfies all those involved. That would correspond to an attributive evaluation in regular samples = Q4.

3. Result

Technological knowledge determines which characteristic becomes a Special Characteristic.

The prerequisite for a SC is that it has a particularly significant influence in the chain of action – the process characteristic on the product characteristic, the product characteristic on the function of the product.

Only as many Special Characteristics as necessary are determined, and also as few as possible. This creates acceptance.

The FMEA as a quality tool helps to grasp these connections and link them via the failure network.

Technological knowledge from templates should be used. Alongside the cause-effect relationships of the network, the main characteristics should also be shown.

Software can apply or verify the 3 rules in this network.

Ideally, the technological knowledge from the template FMEA not only specifies main characteristics, but also the typical quality requirements on these main characteristics. The test plan is thus kept as extensive as necessary and as simple as possible.

And, in this way, FMEA also gains a further degree of importance and reputation, just as all those responsible for FMEA would like it to.