Holistic safety and risk assessment - possible uses of an ERP-integrated FMEA in SAP

from Dr. Gerhard Kicherer, KTT UG

Description of the advantages and flexible application options of an ERP-integrated FMEA for the integrated, holistic safety and risk assessment of products, processes and the reliability of systems, equipment and tools in SAP.

Holistic safety and risk assessment with an ERP-integrated FMEA in SAP; Flexible application options of an SAP ERP-integrated FMEA in the sense of a risk-based closed-loop inspection planning for Product and processes, SAP closed-loop RCM solution, SAP closed-loop TPM solution as well as for Introduction and implementation of an HACCP concept in SAP.

1. Challenge / task:

A holistic security and risk assessment to ensure system security, taking into account all relevant security domains and threats, as well as their influencing factors and dependencies, is becoming increasingly important. The integrated and adapted basic method here is the FMEA method for a risk analysis and evaluation as well as the derivation of optimization measures for different security and risk areas.

The ERP-integrated flexible use of the FMEA method is particularly advantageous and sensible when it comes to an integrated perspective and holistic risk assessment. Only through an integrated perspective is it possible to create a holistic picture of the risks and hazards and to efficiently evaluate and master the dependencies and overlaps.

In the following, the advantage and the flexible application possibilities of an integrated FMEA as offered by SAP will be explained using concrete examples.

Specifically, this is about the Flexible application options of an SAP ERP-integrated FMEA for the integrated, holistic safety and risk assessment of the product, processes, the reliability of systems, equipment and tools, as well as for the development and implementation of a HACCP concept and control plan for the risk-reduced, controlled and correct handling of food.

2. Objective (Why?):

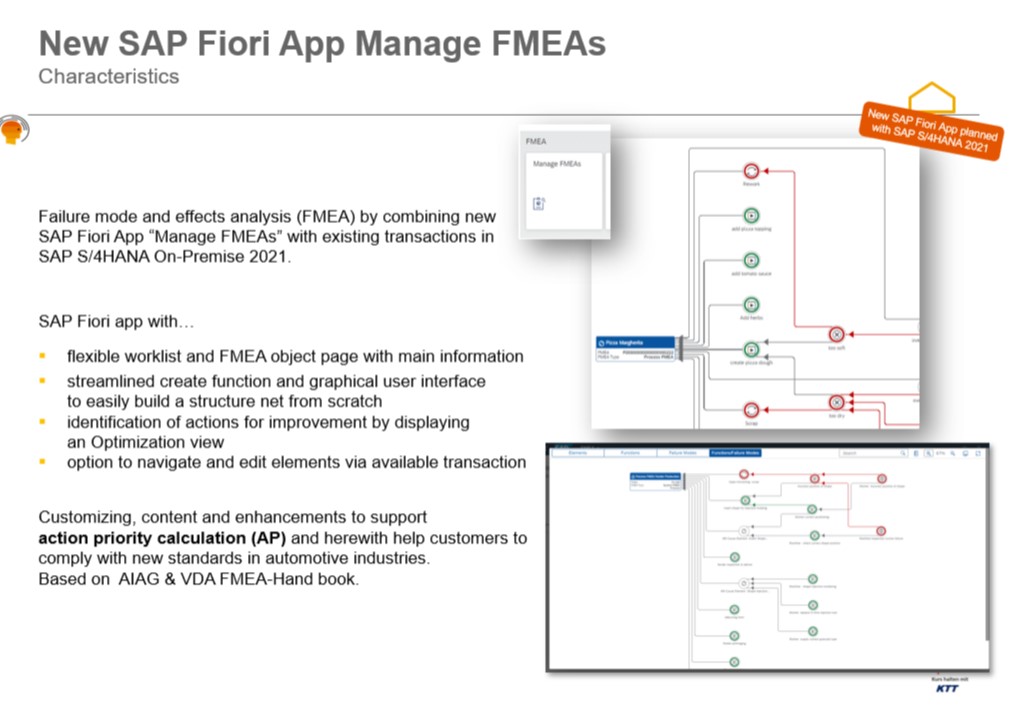

In the following, the functions, the new graphic user interface of the FMEA App in SAP S/4 and the flexibility of the configurable SAP FMEA are explained using examples.

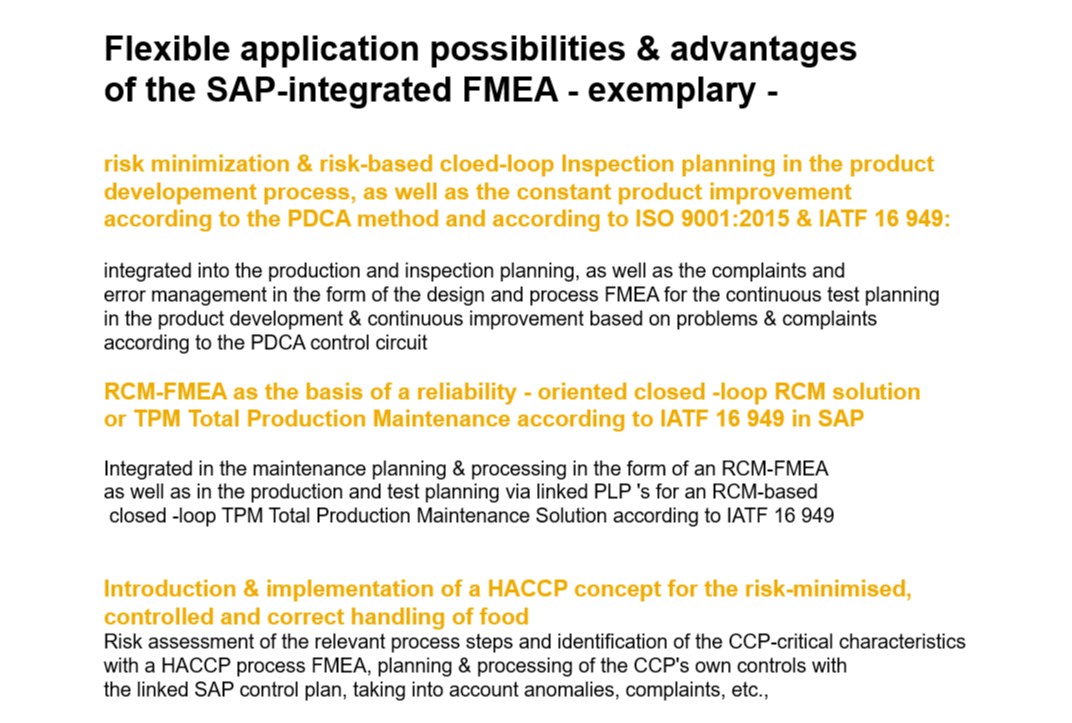

In particular, the flexible application possibilities of the SAP ERP-integrated FMEA

- in the sense of an SAP closed -loop RCM solution for improving the reliability of systems, equipment and tools

- as well as an SAP closed - loop TPM Total Production Maintenance Solution as required by IATF 16 949

- and risk minimization & risk-based continuous inspection planning in the product development process, as well as continuous product and process improvement according to the PDCA method and according to ISO 9001:2015 & IATF 16 949

- Introduction & implementation of a HACCP concept for the risk-reduced, controlled and correct handling of food

3. Approach (How?)

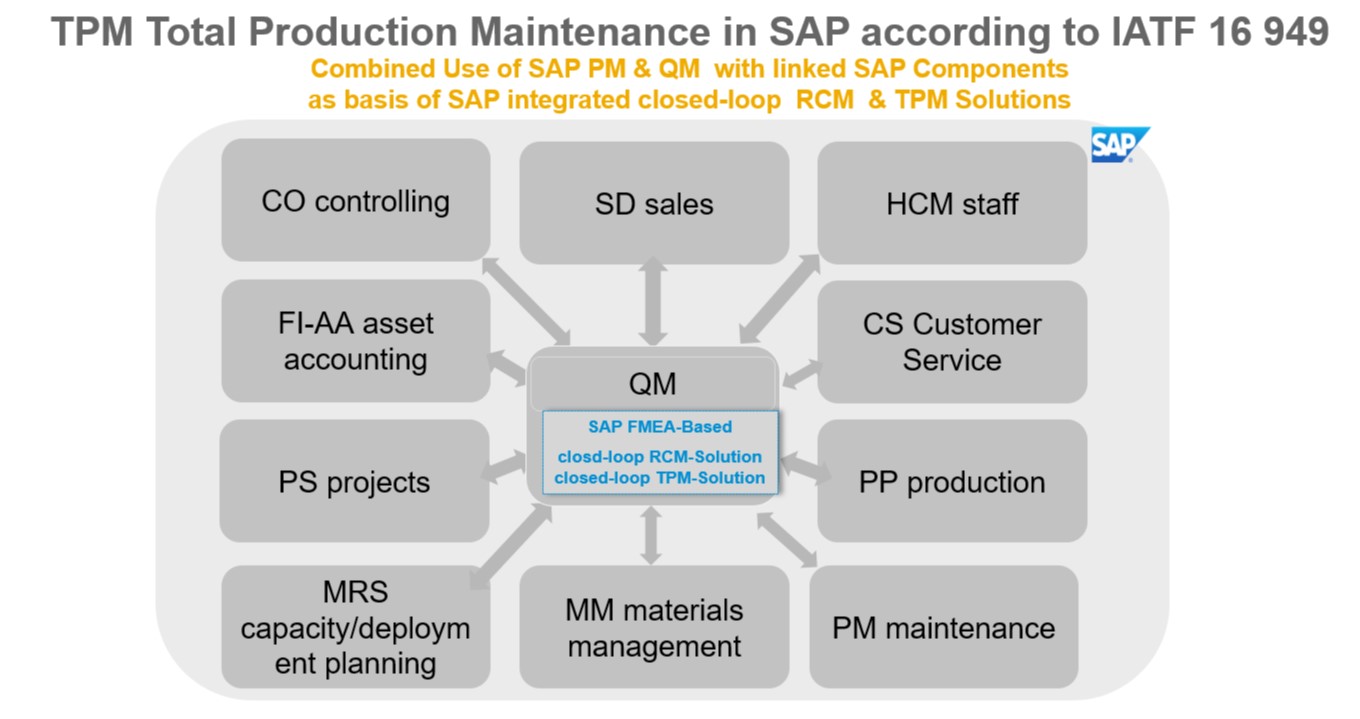

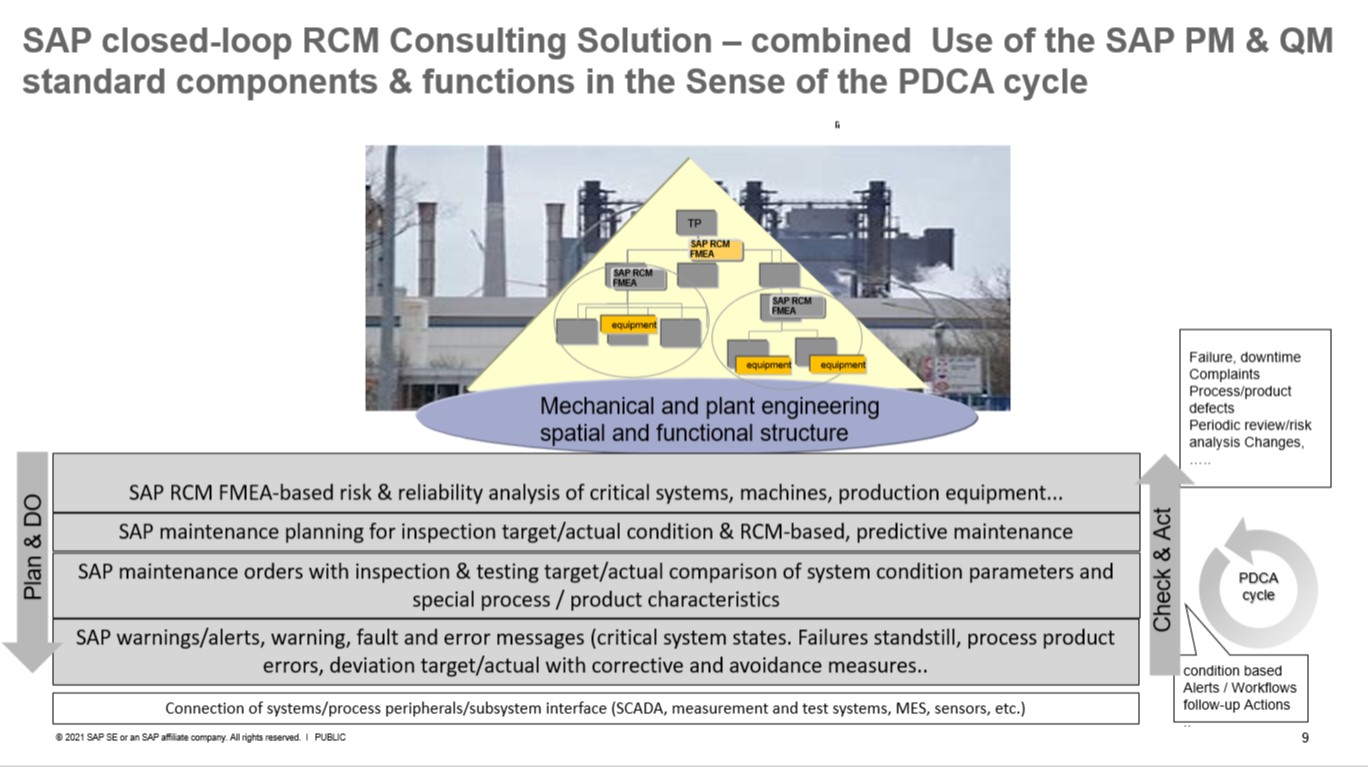

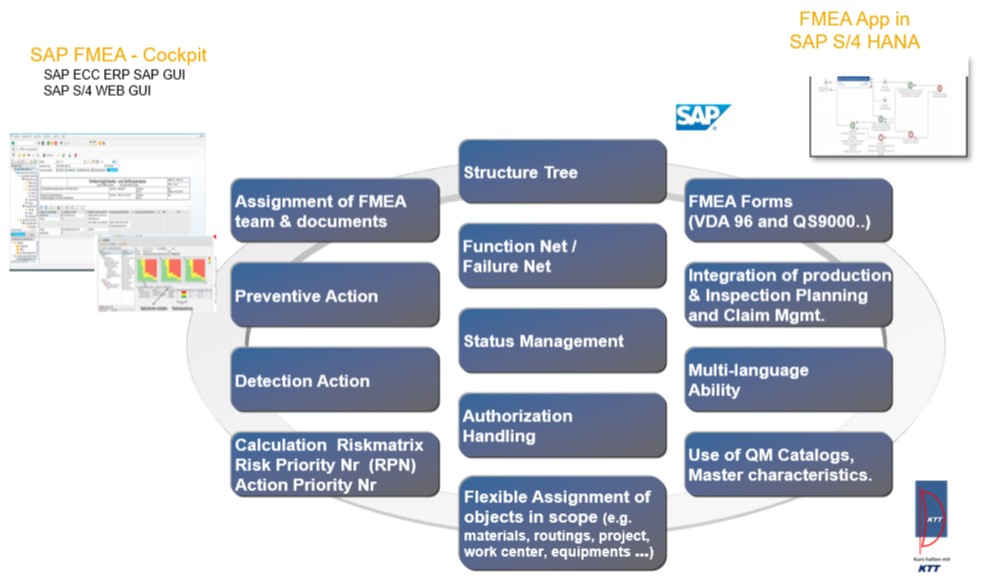

The SAP-integrated, configurable FMEA can be used flexibly with different configurable FMEA types (Design FMEA, Process FMEA, Machine FMEA, RCM asset FMEA..) combined with appropriate object-Types (Materials, Routings, Bill of Materials, Production Equipment...) for FMEA scoping. All these parameters can be customized and configured in combination with other SAP components (SAP PP, MM, PM ..) as shown in Fig. 1. The functional range of the SAP FMEA is shown in Fig. 2, the features of the new graphical user interface & features of the FMEA App in SAP S/4 are shown in Fig. 3.

Area of application: SAP FMEA in the product development process, as well as continuous product improvement according to the PDCA method and according to ISO 9001:2015 & IATF 16 949

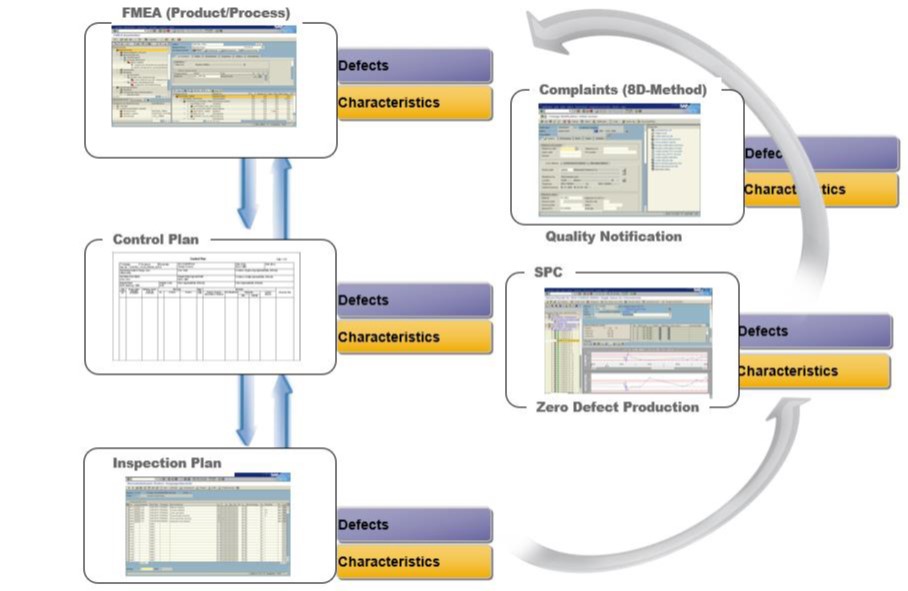

Use of SAP FMEA integrated into production and quality planning, as well as complaints and error management in the form of design and process FMEA for continuous test planning in product development & continuous improvement based on problems & complaints according to the PDCA control cycle

- SAP Failure Mode and Impact Analysis (FMEA) as Standard method of reduction of risks and mistakes already during planning and Development.

- SAP production control plan for documentation of all required process steps and Phases in product development from prototype to serial production. Based on the SAP parts lists, work plans and test plans, as well as integration of the linked FMEAs with the Possibility of taking over characteristics in the PLP.

- Highlights: Direct adaptation of SAP work plans and test plans without redundant data maintenance. Direct feedback of problems in the FMEA & PLP for error avoidance and continuous product and process improvement or the continuous update of the risk assessment & minimization in terms of the PDCA control loop

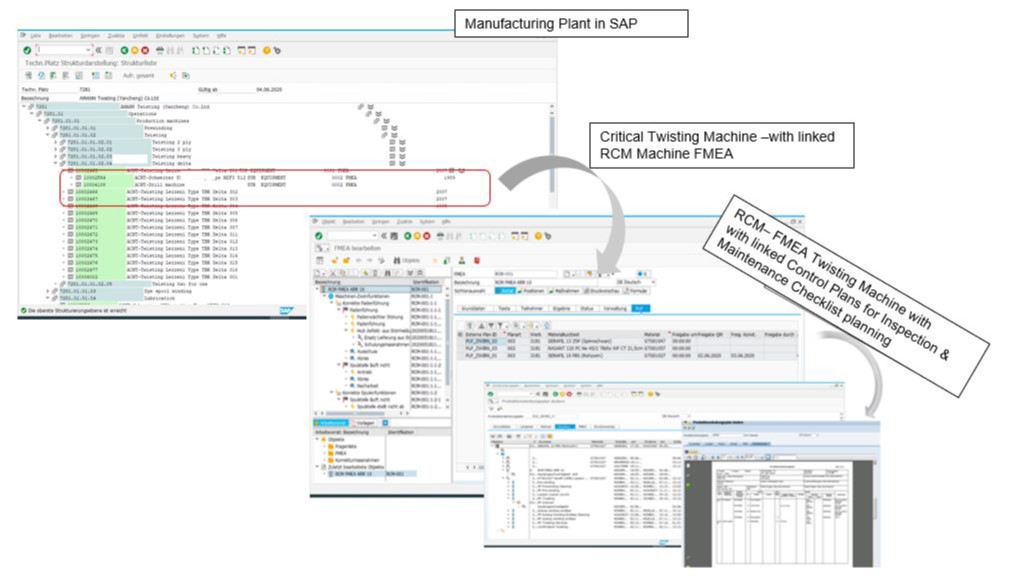

Area of application: RCM-FMEA as the basis of a reliability-oriented, closed-loop RCM solution in SAP and in an extended form by combining the PLP's in the scope as a TPM Total Production Maintenance Solution according to IATF 16 949 in SAP

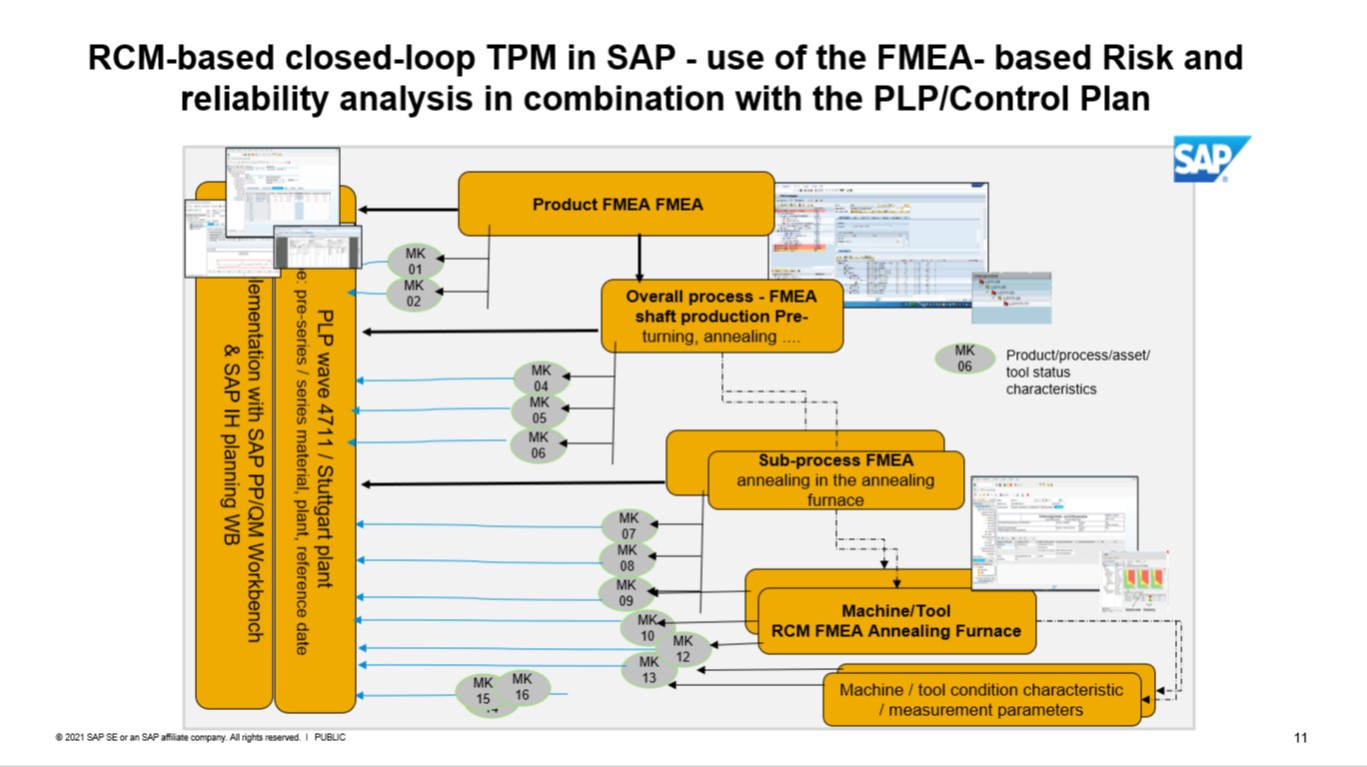

Features: Use of the SAP FMEA in Form of an RCM-FMEA or Machine-FMEA as basis of an SAP-integrated RCM solution for the determination and planning a predictive, reliability-oriented maintenance strategy. In combination with the production control plans PLP's of the products in the scope this RCM-solution can be used as a closed - loop TPM Total Production Maintenance Solution according to IATF 16 949 in SAP.

Challenge in many companies

Increasing cost and competitive pressure, as well as increased demands on plant availability and reliability” How can I reduce the maintenance costs without losing the reliability and availability of my production plants or how can I increase the reliability and availability of my plants without increasing the maintenance costs and compliant products produce in the required quality? "

Suitable methods & IT solution:

Use of the predictive, reliability-oriented maintenance RCM Reliability - Centered -Maintenance method based on the FMEA, closed -loop and integrated in SAP in the sense of TPM Total Production Maintenance, as required by IATF 16 949 in the automotive sector

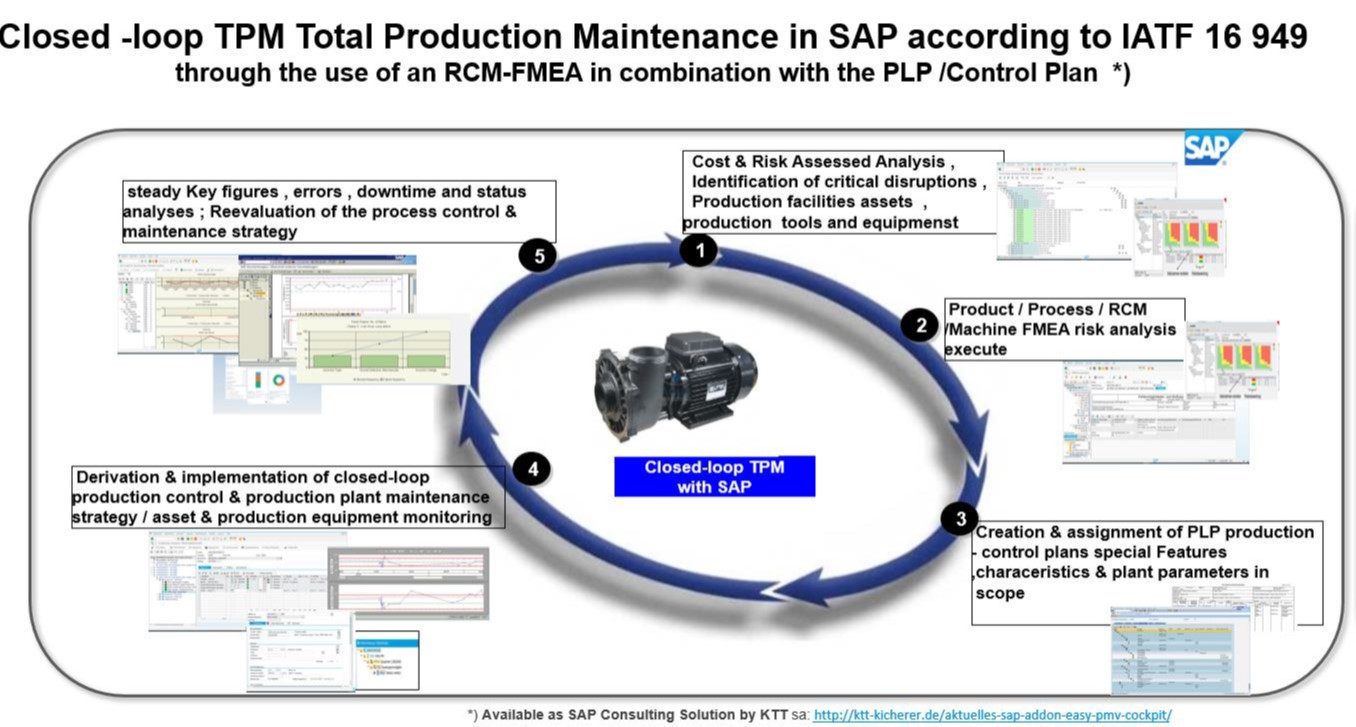

Mapping in SAP with the RCM- based closed - loop TPM

The reliability analysis, the derivation and implementation of suitable action plans and maintenance strategies are carried out by SAP-integrated RCM FMEA's in combination with the linked PLP production control plans, taking into account the probable, but also the actual plant conditions and malfunctions.

By a holistic Safety and risk analysis based on the SAP-integrated FMEA makes it possible to evaluate and increase the reliability and availability of the production systems and to manufacture compliant products within the specifications and required quality as required by IAFT 16 949 in the sense of a TPM strategy.

The implementation of these IATF requirements according to a TPM strategy can be carried out step by step with the help of the SAP integrated PLP production control plan in combination with the product, process and SAP RCM FMEAs, see Fig. 6,10.

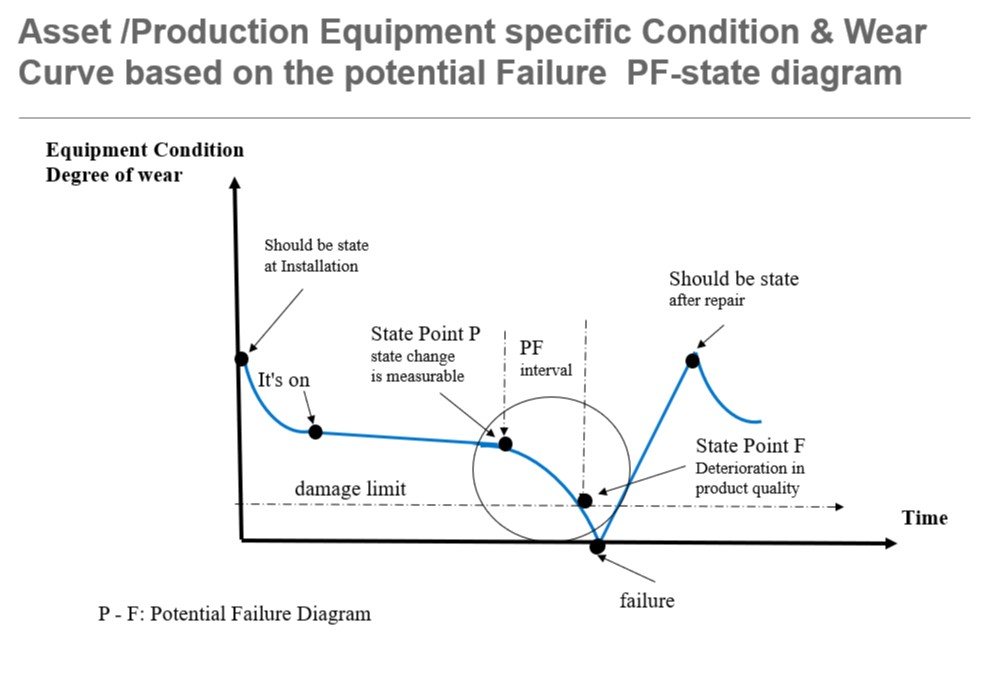

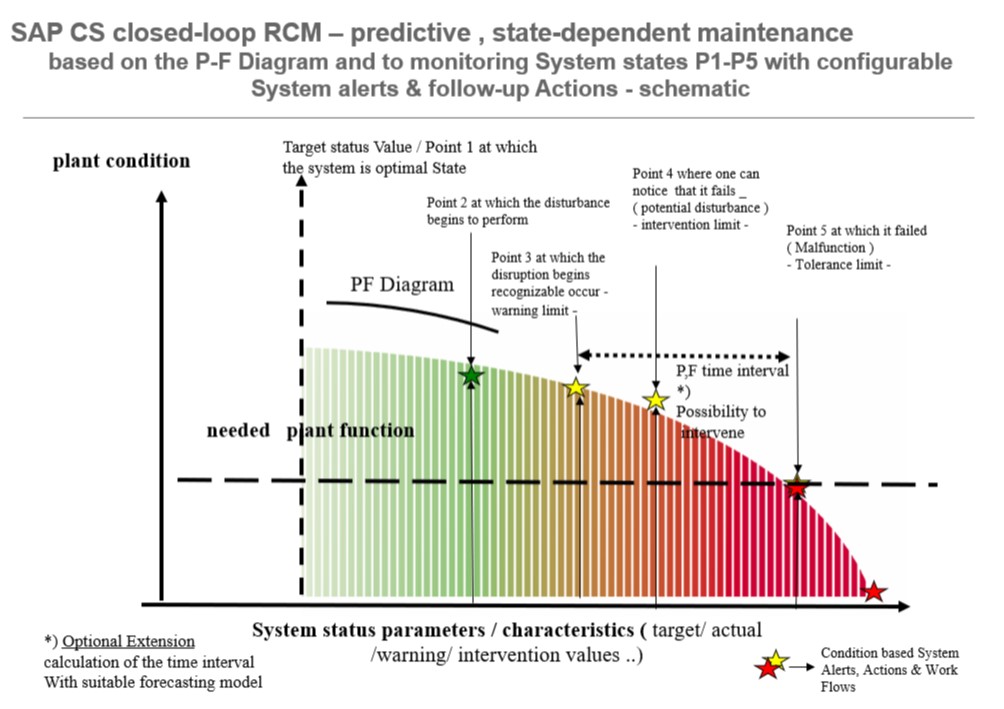

The PLP Control Plan represents the link between the FMEA-based risk analysis of production, the activities in production and the reliability-oriented maintenance of the machines and production systems used for production. The PLP Control Plan includes all special product, process characteristics and system features/parameters: Product Characteristics with specification/tolerance as well as critical production process parameters including system status /Setting parameters as wells as their warning and target values & tolerance according to the PF potential Failure diagrams (Fig. 7,9). These product characteristics and critical production process parameters are derived from FMEA risk and reliability analyses, as well as from customer, product or process specifications see Fig. 7,8) with assigned control methods & reaction plans.

Conclusion:

Advantages of FMEA-based SAP-integrated closed-loop RCM- and TPM solution

- Reference to the manufacturing plant structure with functional location/equip-ment as the leading object

- with direct jump from/to the RCM/FMEA analysis as well as from/to PM and PP objects: maintenance plans, work plans, inspection plans, measuring points, notifications, orders, inspection lots, PLP /Control Plan ..

- the user moves in an integrated, visually guiding user interface SAP Manufac-turing structure, FMEA cockpit / Monitor, PLP Control Plan Cockpit …

- the FMEA methodology is an important element of the IATF 16949 standard. The basis of the RCM rests on the FMEA decision -making mechanisms.

- enables the flexible configuration of closed-loop SAP-integrated RCM-Solutions

- enables the flexible configuration of closed-loop SAP-integrated TPM solutions according to the requirements of IATF 16 949 by using the FMEA-based RCM method for critical production systems, assets and machines in combination with the PLP Control Plans in Scope for a closed-loop Inspection and Mainte-nance Checklist planning

- Target/actual status comparisons with automatic generation of SAP messages with configurable work flows and follow-up actions in the event of a violation of warning/intervention target limits of critical system parameters and process/product characteristics

- The solutions are modular and can be used optional in combination with other SAP Components

- eAM Easy Asset Management Cockpit

- A mobile solution can be integrated

- Use in SAP S/4 HANA with alternative use of the new SAP FIORI app with graphical user interface.

- Use of E-Learning

- Failure Mode Analytics SAP Predictive Maintenance Optional Connection to SAP Manufacturing Digital Cloud & MES Systems via available SAP Interface Technics like Plant Connectivity, Interface-Service, QM-IDI Interface …

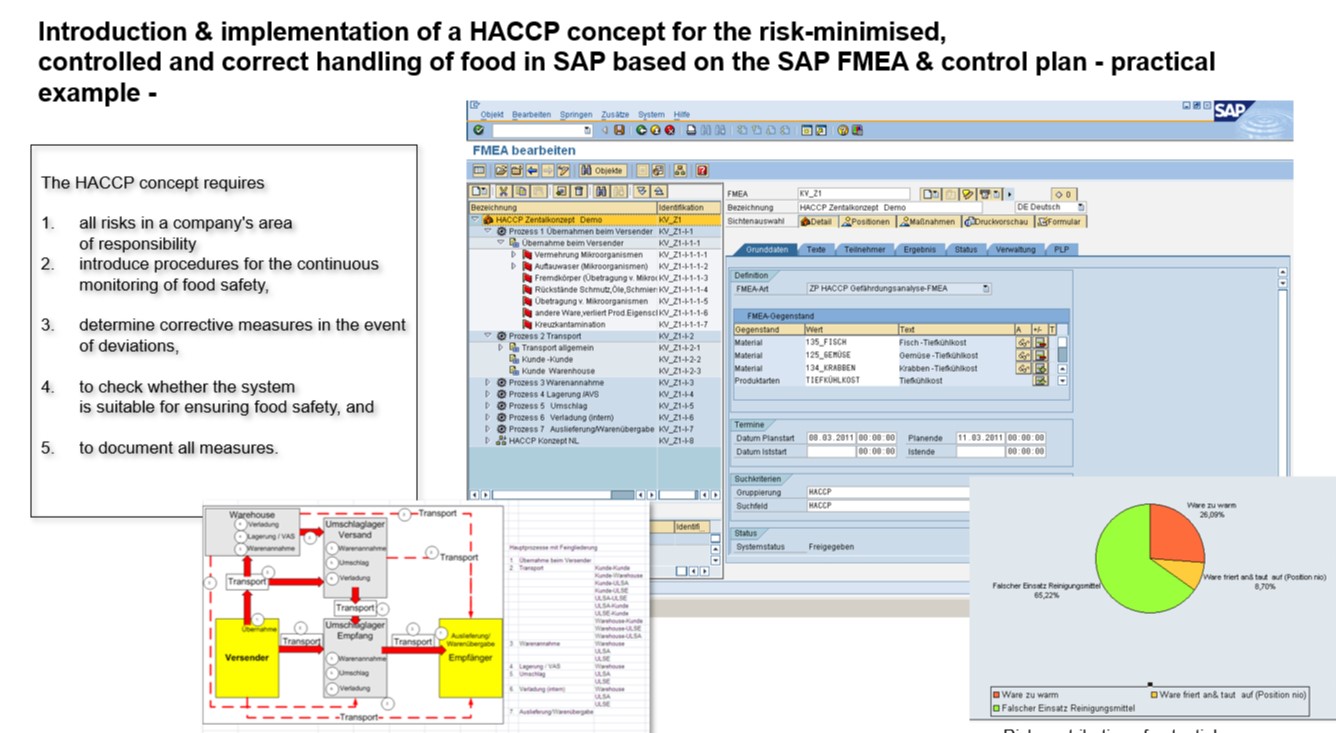

Area of application: Introduction & implementation of a HACCP concept for the risk-minimised, controlled and correct handling of food

Necessary introductory steps for an HACCP concept:

- all risks for the tolerance of the food in the area of responsibility of a company,

- to determine the critical points for food monitoring,

- Define intervention limits for the critical control points,

- introduce procedures for the continuous monitoring of food safety,

- determine corrective measures in the event of deviations,

- to check whether the system is suitable for ensuring food safety, and

- to document all measures.

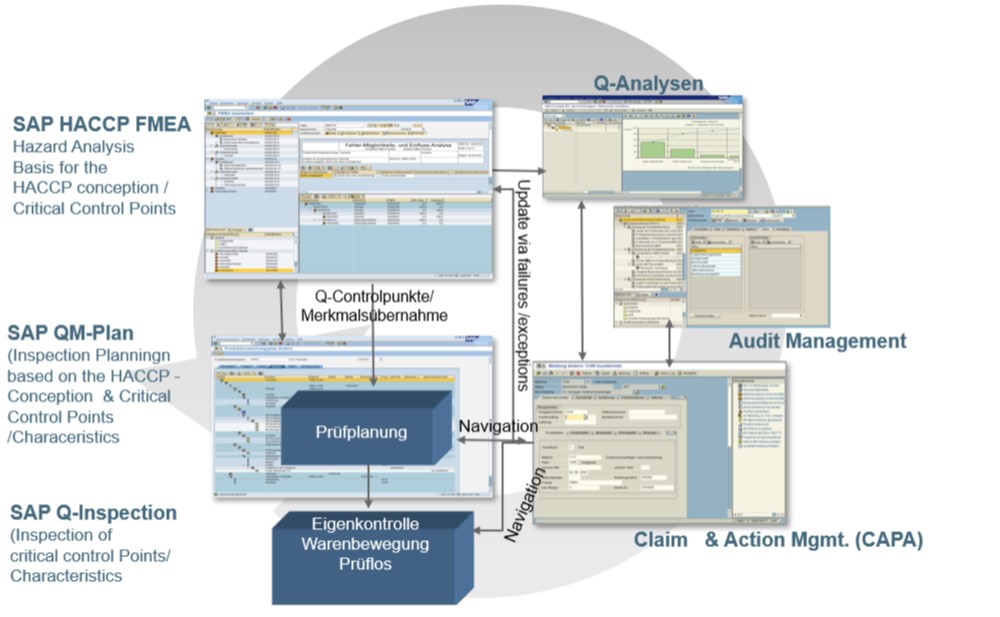

In SAP, the introduction and implementation of an HACCP concept can be supported as follows, see Fig. 10 and 11:

- Risk assessment of the relevant process steps and identification of the CCP-critical characteristics with a HACCP Process FMEA as well

- Derivation and creation of a HACCP SAP control plan with specifications for the CCP's own controls and monitoring procedures

- Planning, implementation, processing and documentation of the CCP's own controls with the linked SAP control plan, taking into account anomalies, complaints, etc.,

- Documentation of deviations, abnormalities, complaints and measures with SAP Q reports

4. Result

Summary - References to Customer Set Reports & Publications

Risk-based approaches and procedures, as well as holistic security and risk assessments to ensure system security, taking into account all relevant security domains and threats, as well as their influencing factors and interdependencies, are becoming increasingly important and are also required in relevant standards. The integrated, flexible use of the FMEA method is suitable as a basic method here.

The ERP-integrated FMEA from SAP supports the company with a flexible, configurable tool for risk analysis and evaluation and the derivation of comprehensive optimization measures for different safety and risk areas.

Advantages and the flexible application possibilities of an integrated FMEA as offered by SAP could be explained in the article using concrete examples.Specifically, this was about the Flexible application options of an SAP ERP-integrated FMEA for the integrated, holistic safety and risk assessment of the product, processes, the reliability of systems, equipment and tools, as well as for the development and implementation of a HACCP concept and control plan for the risk-reduced, controlled and correct handling of food.

Reference to further information, customer reports and publications

- Control Messe Stuttgart 05.Mai 2022 Stuttgart

Presentation Trade Fair Forum "SAP S/4 HANA QM Innovations and Additional Solutions for Simplified Inspection and Equipment Monitoring"Claus Bruckner, SAP SE & Co. KG Deutschland

Dr. Gerhard Kicherer, KTT Kicherer Training & Tools UGControl - Trade fair presentation by SAP & KTT Showroom (control-messe.de)

- Maintenance Days September 20, 2021 Dortmund

"SAP add-on solutions in maintenance for simplified gauge management, closed-loop RCM and TPM Solution "

Edwin Henne, ArcelorMittal /Ghent

Dr. Gerhard Kicherer, KTT UG - SAP Info Day Integrated CAQ - September 16, 2020.

Possible uses of SAP-integrated FMEA - mapping and planned support with the new FMEA App in SAP S/4HANA.Dr. Helmut Haesslein, SAP S/4 QM Development, SAP SE

Dr. Gerhard Kicherer, KTT Kicherer Training & Tools UG - SAP add-on solutions in QM and PM maintenance.

SAP Integrated closed-loop RCM Solution;

SAP Integrated closed-loop TPM Solution - DSAG Annual Congress September 27, 2017

Optimizing maintenance through an SAP ERP integrated RCM Reliability Centered Maintenance Solution based on FMEA methodology.Stefan Vieth , ArcelorMittal Bremen GmbH , Bremen

Dr. Gerhard Kicherer , KTT Kicherer Training & Tools UG , Steinheim /MurrDSAG Annual Congress 2017 - Invitation (schaller-digital.de)